When the vibrating screen is screening material, the materials will do circular motion on the box, so it is also called circular vibrating screen.

Max.Feeding size: 400mm

Processing capacity: 8-800m³/h

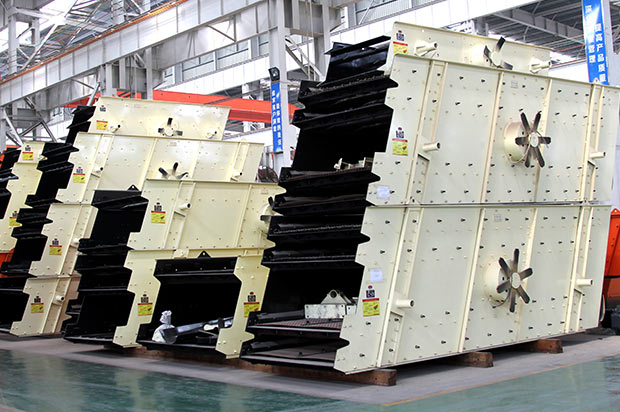

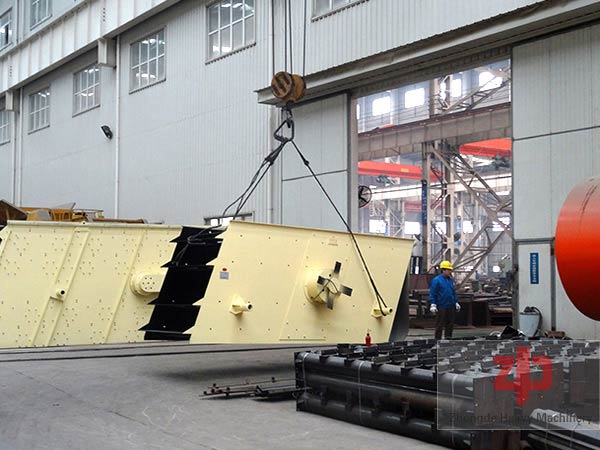

The vibration screen produced by company is the new kind of screening equipment, which is developed on the basis of customers' feedbacks. It adopts German advanced research, development and manufacturing technology. It can screen relatively massive material and small granular materials for the grading operations. Vibrating screen not only can be used alone in the production line, but also can be used in the mobile crushing plant, which is the most ideal equipment for mobile screen plant.

The mesh layer and mesh size of circular vibrating screen can be selected according to the material classification requirements. The equipment has strong processing capacity and high screening efficiency, so it is widely used in sand quarry, concrete mixing station, dry mortar, power plant desulfurization, metallurgy industry, etc.

1. Spring damping function can protect the equipment and the original integrity of materials.

2. Thin oil lubrication, long using period of the bearing and longer service life of the whole machine.

3. Simple and convenient repair and maintenance, the operation of the machine has been improved obviously.

4. Higher screening efficiency, higher processing capacity, which is 1.3-2 times higher the ordinary vibrating screen.

5. Simple structure, convenient disassembly and replacement of the sieve surface, and it can be disassembled for transport.

Before starting the vibrating screen, you should check whether the fasten bolts are loose, if loose, it should be retightened. Vibration screen surface should be initiated in the absence of material, try to avoid the start with materials, when the screening machine is running smoothly, start to feed. Before stopping the machine, stop feeding at first, when the surface has no material, stop the screen.

Always check the situations of wearing parts, if the damping spring is damaged or lost elasticity, they must be promptly replaced. You should always observe the operation conditions of the screen, if abnormal movement or abnormal sound is found, timely shut down to check, find out the reasons and then remove the failure.

If you want to find China vibrating screen manufacturer, Zhongde Heavy Industries is a good choice. With many years of production and sale experience, we will offer you high quality vibrating screen with reasonable price and considerate service. Welcome to contact us!

| Model | Sieve Layer | Sieve Area (㎡) |

Processing capacity (m³/h) |

| 2YK1230 | 2 | 7.2 | 12-78 |

| 3YK1230 | 3 | 10.8 | 13-80 |

| 2YK1237 | 2 | 8.88 | 15-86 |

| 3YK1237 | 3 | 13.32 | 16-90 |

| 2YK1548 | 2 | 14.4 | 22.5-162 |

| 3YK1548 | 3 | 21.6 | 22.5-162 |

| 4YK1548 | 4 | 28.8 | 22.5-162 |

| 2YK1854 | 2 | 19.44 | 32-312 |

| 3YK1854 | 3 | 29.16 | 32-312 |

| 4YK1854 | 4 | 38.88 | 32-336 |

| 2YK2160 | 2 | 25.2 | 50-475 |

| 3YK2160 | 3 | 37.8 | 50-475 |

| 4YK2160 | 4 | 50.4 | 50-497 |

| 2YK2460 | 2 | 28.8 | 65-550 |

| 3YK2460 | 3 | 43.2 | 70-620 |

| 4YK2460 | 4 | 57.6 | 80-680 |

| 2YK2866 | 2 | 31 | 70-650 |

| 3YK2866 | 3 | 47 | 80-700 |

| 4YK2866 | 4 | 62 | 90-750 |

| 2YK2873 | 2 | 39.2 | 70-680 |

| 3YK2873 | 3 | 58.8 | 80-720 |

| 4YK2873 | 4 | 58.8 | 90-950 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

NOTE: You can also send a message to us by this email info@sinoftm.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!