Sand dryer is characterized by the different uses, sizes and humidity requirements of sand.

Applied Materials:slag, limestone, limestone, coal ash, coal dust, clay

Capacity:1.9-76TPH

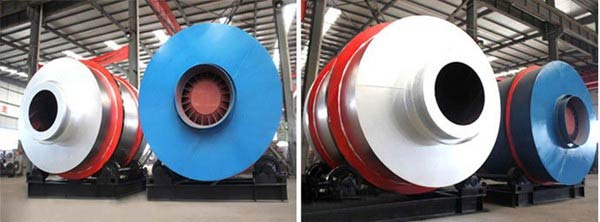

Sand is more and more widely used in daily life and industry production. Because of the application and transport needs, it needs to be dried before transport. Sand dryer emerges as the times require, which is also known as yellow sand drying machine. Sand dryer is characterized by the different uses, sizes and humidity requirements of sand. The basic property of the sand drying machine is that it needs to meet the drying of different particle size requirements and different water content of sand.

In the drying process of particle size and moisture content of materials, sand dryer has certain requirements. It is more suitable for drying yellow sand in the powder mortar, various types and specifications sand used in the casting industry, the blast furnace slag in cement building materials industry and smoke particle materials in chemical industries which are not afraid of high temperature.

The commonly used drying machine is developed on the basis of traditional three cylinder drying machine. So sand dryer inherits the characteristics of the three cylinder drying machine, and it has special drying effect on the drying operation of sand based on the high humidity and high proportion characteristics of sand. Sand drying machine also has its own unique advantages:

1. Small equipment investment, low operation cost, small occupied area.

2. Strong adaptability, which can meet different drying needs of different granularity sand.

3. Convective drying, high drying rate, good drying effect, the final moisture content can be controlled.

4. The inner lifter has higher drying efficiency, and the sand is not easy to stick together, thus resulting in uneven drying.

5. It is equipped with the automatic cleaning device.

6. The discharge temperature is less than 60 degrees, and there is no need to cool before packaging.

7. Environmental protection, good sealing performance, excellent working environment.

Zhognde Heavy Industries is the experienced sand dryer manufacturer in China, and we also have small sand dryer for sale. Even though our sand dryer price is favorable, our quality and service are the best. During the installation and commissioning of the dryer, it you have any problem that cannot be solved, it will affect the normal operation of the equipment, so we want to make sure that you have done the correct installation and repeated debugging, when everything is normal, it can be put into operation. Buying sand drying machine from our company can solve your any menace from the rear. We will also provide on-site installation guide service for you.

| Spec./m (Dia.×Length) |

Capacity (t/h) |

Highest Inlet Air Temperature (℃) |

| Φ1.2×8.0 | 1.9~2.4 | 700~800 |

| Φ1.2×10 | 2.4~3.0 | 700~800 |

| Φ1.5×12 | 4.5~5.7 | 700~800 |

| Φ1.5×14 | 5.3~6.6 | 700~800 |

| Φ1.5×15 | 5.7~7.1 | 700~800 |

| Φ1.8×12 | 6.5~8.1 | 700~800 |

| Φ1.8×14 | 7.6~9.5 | 700~800 |

| Φ2.2×12 | 9.7~12.2 | 700~800 |

| Φ2.2×14 | 11.4~14.2 | 700~800 |

| Φ2.2×16 | 13.0~16.2 | 700~800 |

| Φ2.4×14 | 13.5~16.9 | 700~800 |

| Φ2.4×18 | 17.4~21.7 | 700~800 |

| Φ2.4×20 | 19.3~24.1 | 700~800 |

| Φ2.4×22 | 21.2~26.5 | 700~800 |

| Φ2.6×24 | 27.2~34.0 | 700~800 |

| Φ3.0×20 | 30.1~37.7 | 700~800 |

| Φ3.0×25 | 37.7~47.1 | 700~800 |

| Φ3.2×25 | 42.9~53.6 | 700~800 |

| Φ3.6×28 | 60.8~76.0 | 700~800 |

Technical parameters of indirect heat dryer:

| Shell diameter ×shell Length Items |

Shell cubage (m³) |

Highest inlet air temperature (℃) |

| Φ1.5×15m | 20.27 | 850 |

| Φ1.5×17m | 22.97 | |

| Φ1.5×19m | 25.68 | |

| Φ1.8×21m | 35.91 | 850 |

| Φ1.8×23m | 39.33 | |

| Φ1.8×25m | 42.75 | |

| Φ2.2×21m | 58.10 | 850 |

| Φ2.2×23m | 63.61 | |

| Φ2.2×25m | 69.15 |

NOTE: You can also send a message to us by this email info@sinoftm.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!