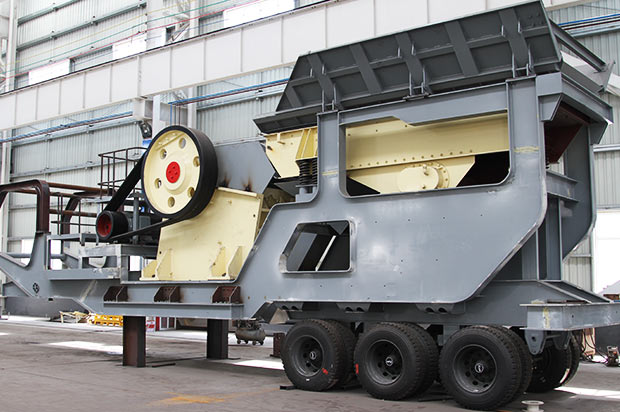

Mobile jaw crushers can be quickly put to work and moved from one location to another, which is suitable for the aggregate, mining, recycling and contracting industries.

Feeding Size: 400-1200mm

Production Capacity: 45-500TPH

Rubber-tyred mobile jaw crusher produced by our company is the ideal crushing equipment of rocks and construction waste, and its appearance has greatly expanded the concept of crushing operations. The unique design concept of rubber-tyred mobile jaw crusher embodies in the elimination of site environment, complicated configuration and complex operation obstacles, which truly provides efficient and low cost operation projects for the customers.

All the components of rubber-tyred mobile jaw crusher are completely vehicle mounted, which is mainly made up of the high efficiency jaw crusher, high performance vibrating screen, belt machine, motor and control box, etc. The coordination work and the integrated installation of the entire unit fully embody its advantages of convenience and flexibility.

1. It is widely used in mining, coal, waste and construction waste recycling, earthwork, city infrastructure, road, construction sites and other field operations.

2. River pebbles, rocks (granite, limestone, basalt, andesite, diabase and so on), ore tailings and artificial sand.

3. The processing of surface soil and a variety of other materials; construction and demolition industry; the separation of viscous coagulation aggregate; the screening after crushing; quarrying industry.

1. Flexible combination, strong adaptability, good mobility;

2. Compact structure, easy to use;

3. High performance, high crushing ratio, uniform product size;

4. Cost savings, reduce costs;

5. Vehicle mounting support, convenient residence of the equipment.

In addition, customers can adopt various configuration modes according to raw material types, sizes and different product requirements. Welcome to contact us for more details!

Model ZD938HD86 and ZD1149HD98

| Model | ZD938HD86 | ZD1149HD98 |

| Transportation lenght(mm) | 12600 | 13500 |

| Transportation Width(mm) | 2600 | 2700 |

| Transportation Height(mm) | 3870 | 4200 |

| Maximum Lenght(mm) | 12500 | 14000 |

| Maximum Width(mm) | 4100 | 4500 |

| Maximum Height(mm) | 4100 | 4900 |

| Weight(t) | 39 | 57 |

| tIRE Configuration | Dualaxial | Dualaxial |

| Jaw Crusher | HD86 | HD98 |

| Maximum Feeding Size(mm) | 500 | 550 |

| Discharge opening range | 50-150 | 75-175 |

| Capacity(t/h) | 85-275 | 110-350 |

| Vibrating Feeder | ZSW380×95 | ZSW420×110 |

| Main Belt Conveyor | B800×8.5m | B1000×9.5m |

| Side-opening Belt conveyor(optional) | B500×3m | B650×3.5m |

| Gensrt(optional) | 200KW | 250KW |

| Iron separator(optional) | RCYD(C)-8 | RCYD(C)-10 |

Model ZD1349HD110 and ZD1349HD125

| Model | ZD1349HD110 | ZD1349HD125 |

| Transportation lenght(mm) | 14500 | 15200 |

| Transportation Width(mm) | 2800 | 2900 |

| Transportation Height(mm) | 4450 | 4500 |

| Maximum Lenght(mm) | 16100 | 16700 |

| Maximum Width(mm) | 5100 | 5100 |

| Maximum Height(mm) | 5000 | 5300 |

| Weight(t) | 55 | 65 |

| Tire Configuration | Dualaxial | Dualaxial |

| Jaw Crusher | HD110 | HD125 |

| Maximum Feeding Size(mm) | 660 | 800 |

| Discharge opening range | 100-200 | 125-225 |

| Capacity(t/h) | 215-510 | 280-650 |

| Vibrating Feeder | ZSW490×130 | ZSW490×130 |

| Main Belt Conveyor | B1000×11m | B1200×11m |

| Side-opening Belt conveyor(optional) | B650×4m | B650×4m |

| Gensrt(optional) | 270KW | 400KW |

| Iron separator(optional) | RCYD(C)-10 | RCYD(C)-12 |

NOTE: You can also send a message to us by this email info@sinoftm.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!