Fly ash is the fine dust collected from the flue gas after coal combustion, which is one of the current industrial waste materials with large amount. If the fly ash is directly emitted into the air without treatment, it will pollute the environment.

Applied Materials:slag, limestone, limestone, coal ash, coal dust, clay

Capacity:1.9-76TPH

Fly ash is the fine dust collected from the flue gas after coal combustion, which is one of the current industrial waste materials with large amount. If the fly ash is directly emitted into the air without treatment, it will pollute the environment. Not only that, it also contains toxic substances to harm people's health.

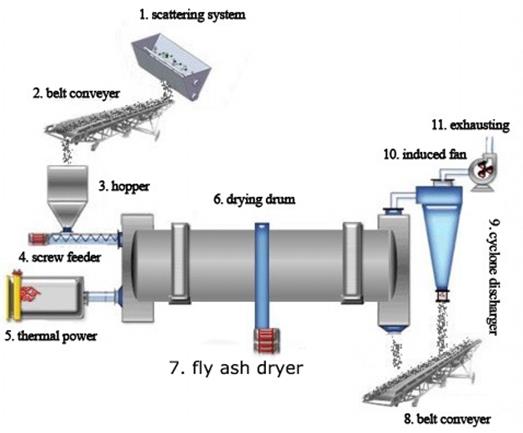

The fly ash after treatment and recovery can be used as cement, mortar and concrete admixtures, and it also can replace clay as raw material for cement production. Fly ash has been widely used in various industries, which not only solves the fly ash air pollution problems, but also realizes the reuse of waste, which has killed two birds with one stone. The direct collection of fly ash not only has uneven granule, its humidity is particularly large with light weight, which cannot be directly used in building materials industry. The first step for the treatment of fly ash is to dry, our company has specially developed fly ash drying machine models according to the characteristics of fly ash.

1. Less investment.

2. Low energy consumption, energy saving and environmental protection.

3. High drying efficiency, the feeding requirements for moisture content is not high.

4. Good sealing effect, which can prevent fly ash particles entering into the air to cause dust pollution.

5. It uses alloy steel casting, which has longer service life than the traditional steel equipment.

6. The material moisture content can be adjusted according to actual needs.

7. It is equipped with dust removal device.

1. Because the water content of directly collected fly ash has reached 45%, the direct drying production cost has been greatly increased, so the material should be placed in a well ventilated place for a period of time, and then it can be dried.

2. For low water content materials, it should be sealed for the shipping transportation.

3. Before using the equipment, you should carefully read the instructions. The emerged problem should be timely solved.

As the professional fly ash drying machine manufacturer in China, Zhognde Heavy Industries has various models of fly ash dryer for sale. When it comes to fly ash dryer machine price, we have the lowest quotation with the highest quality. If you are in need, please contact us or pay a visit to our company.

| Spec./m (Dia.×Length) |

Capacity (t/h) |

Highest Inlet Air Temperature (℃) |

| Φ1.2×8.0 | 1.9~2.4 | 700~800 |

| Φ1.2×10 | 2.4~3.0 | 700~800 |

| Φ1.5×12 | 4.5~5.7 | 700~800 |

| Φ1.5×14 | 5.3~6.6 | 700~800 |

| Φ1.5×15 | 5.7~7.1 | 700~800 |

| Φ1.8×12 | 6.5~8.1 | 700~800 |

| Φ1.8×14 | 7.6~9.5 | 700~800 |

| Φ2.2×12 | 9.7~12.2 | 700~800 |

| Φ2.2×14 | 11.4~14.2 | 700~800 |

| Φ2.2×16 | 13.0~16.2 | 700~800 |

| Φ2.4×14 | 13.5~16.9 | 700~800 |

| Φ2.4×18 | 17.4~21.7 | 700~800 |

| Φ2.4×20 | 19.3~24.1 | 700~800 |

| Φ2.4×22 | 21.2~26.5 | 700~800 |

| Φ2.6×24 | 27.2~34.0 | 700~800 |

| Φ3.0×20 | 30.1~37.7 | 700~800 |

| Φ3.0×25 | 37.7~47.1 | 700~800 |

| Φ3.2×25 | 42.9~53.6 | 700~800 |

| Φ3.6×28 | 60.8~76.0 | 700~800 |

Technical parameters of indirect heat dryer:

| Shell diameter ×shell Length Items |

Shell cubage (m³) |

Highest inlet air temperature (℃) |

| Φ1.5×15m | 20.27 | 850 |

| Φ1.5×17m | 22.97 | |

| Φ1.5×19m | 25.68 | |

| Φ1.8×21m | 35.91 | 850 |

| Φ1.8×23m | 39.33 | |

| Φ1.8×25m | 42.75 | |

| Φ2.2×21m | 58.10 | 850 |

| Φ2.2×23m | 63.61 | |

| Φ2.2×25m | 69.15 |

NOTE: You can also send a message to us by this email info@sinoftm.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!