Dry powder briquette machine is suitable to press dry powdery materials into briquettes, which belongs to briquette making machine.

Power: 37-55kw

Capacity: 1-18TPH

Dry powder briquette machine is suitable to press dry powdery materials into briquettes, which belongs to briquette making machine.

In industries of smelting, building material, chemical, mining and others, there are numerous kinds of industrial and mineral powder materials should be briquetted before utilized in smelting or fire modification, so as to be recycled, add value and meet environmental protection requirements. Many of these materials are not allowed to add adhesive or water in briquetting, thus they need to be processed by dry powder briquette machine.

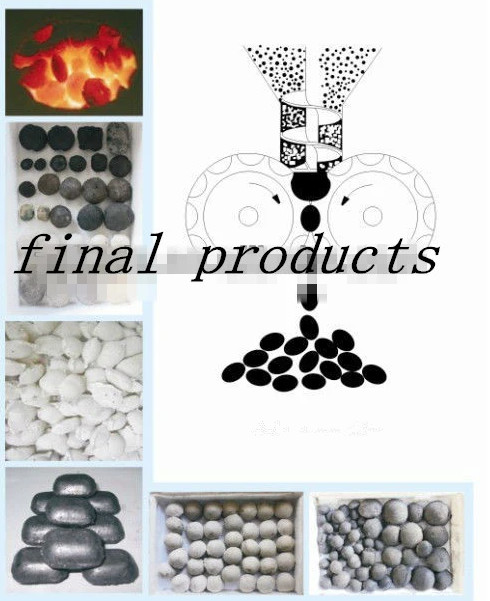

High Pressure Dry Powder Briquette Press Machine is widely used to make briquettes from various powdery materials, including aluminium powder, magnesium powder, ore powder, active charcoal powder, alumina, caustic soda (sodium hydroxide), clay, coke powder, coal, cryolite, chemical fertilizer, plastic, calces, pigment etc. without using binder. The main purpose of the machine is to reduce powder pollution, minimize size/capacity of raw material, recycle and make more it convenient for transportation. In the steel mills, lime plants, metallurgy, refractory furnace charge, metal magnesium powder white powder industries, briquetting is extensively used.

This briquette press machine is characterized by high efficiency and low power consumption, compact structure and so on.

1. Size of raw material: 80-200 mesh

2. There shouldn't be any metallic material in the raw material to avoid damaging the surface of rollers.

3. Sufficient supply of raw material to make perfect and good-looking briquette

4. The moisture of material should be no more than 3

Shape: can be round, pillow, oval.

Size: changeable size 20mm - 80mm, made according to clients requests.

| Model | Roller Diameter (mm) |

Capacity (t/h) |

| FTMQ290 | 290 | 1-2.5 |

| FTMQ360 | 360 | 3-5 |

| Heavy FTMQ360 | 360 | 3-5 |

| FTMQ430 | 430 | 5-8 |

| Heavy FTMQ430 | 430 | 5-8 |

| FTMQ500 | 500 | 8-11 |

| FTMQ650 | 650 | 10-15 |

| FTMQ750 | 750 | 20-25 |

| FTMQ850 | 850 | 20-28 |

| FTMQ1000 | 1000 | 25-35 |

NOTE: You can also send a message to us by this email info@sinoftm.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!