Sand washing machine equipment is an important equipment to improve the quality of sand, in the sand production line, is the soul of the sand machine partner, sand washing machine has a bucket type and spiral two, both have their own advantages, according to the user's production The conditions and the physicochemical properties of the material are selected. A suitable model can increase work efficiency, have better cleaning effect, and have a higher degree of sandstone purity, which is favorable to the production of high-quality sandstone.

In the sand making production line, the materials are processed through multiple processing steps and foreign matter dust is mixed, affecting the finished product taste. In order to obtain clean high-quality sand, the cooperation of sand washing machines is required, and as the number of high-level construction projects gradually increases, The demand for high-quality sandstone continues to rise, which also opens up new technological breakthroughs for the sand washing machine market. Sand washing machine equipment has two major models, bucket sand washing machine and spiral sand washing machine.

The working principle is scientific and reasonable, the sand washing effect is good, and the clarity is high. Compared with the screw type sand washer, the work performance is even better. Therefore, it is the favorite choice of many users. As the impeller rotates slowly, the material enters the cleaning tank and is rolled and grinded by the impeller. The impurities covering the surface of the gravel are washed away, destroying the vapor layer of the coated sand, so as to facilitate dehydration, and the powerful water flow will reduce impurities and specific gravity. Small foreign matter is carried away and discharged from the overflow tank to complete the cleaning process. The clean sand is carried away by the blades and poured from the rotating impeller into the discharge chute to complete the sand stone cleaning operation.

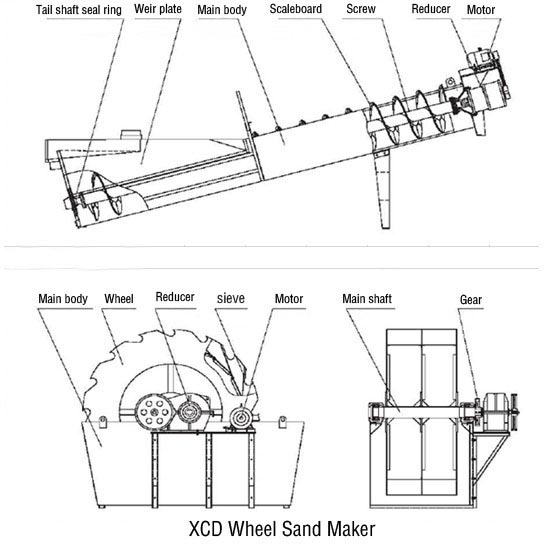

Spiral sand washing machine spiral sand washing device, overflow device, water back device, tailings dry row device, separation and recovery device, water storage tank, water pump, motor, reducer and other components. The material enters the front-end spiral sand washing device via the conveying device, is classified and cleaned, and the rear tailings dry discharge device is used to dehydrate the qualified materials. The remaining wastewater after cleaning (including some qualified materials) enters the back end through the overflow device. The water storage tank is driven into a separation and recovery device by a water pump, and is concentrated and concentrated by centrifugal force. The qualified materials are also dehydrated, and the remaining wastewater is discharged into the water-repellent device.

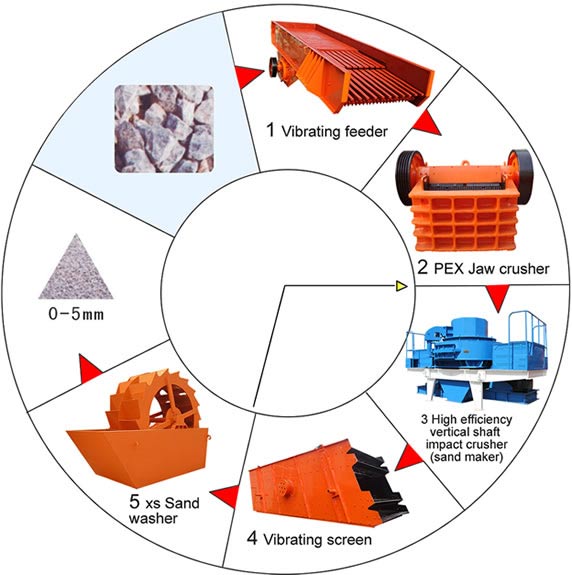

The importance of sand washing machines is obvious. In the sand production line, together with the sand making equipment, the sand making operation is completed. The popularity of the sandstone market has made sand-making equipment manufacturers join the ranks of production, and the mixed market has brought more trouble to users. In order to allow you to quickly select qualified manufacturers, choose the right manufacturers, in order to enjoy preferential prices, excellent quality, advanced technology. Select Zhongde Heavy Industries and give you five reasons to not regret.

We have a professional technical research and development team, and have established good cooperative relations with major universities. There are many high-level talents such as doctors and masters in the team. The technical force is strong, and the technology application can be updated in time to allow users to enjoy new technologies at all times;

Strict material selection can not only ensure the working performance of the equipment, but also reduce the probability of failure, extend the service life of the equipment, reduce operating investment, and have higher comprehensive benefits;

Our equipment models are complete, can also provide tailor-made, customized according to your actual production conditions, equipment performance is better, better adaptability, work more stable;

We are capable of mass production, have a number of production lines, can synchronize production, lower costs, and can provide users with more preferential space and offer better prices;

The perfect after-sales represents our determination to be responsible for the users. We will protect our customers' production all the time. Our equipment is equipped with a lifetime after-sales service to provide installation, commissioning and maintenance work. Once the production process fails, the equipment should be promptly resolved. We get in touch and we will quickly go to the production site to solve problems for you.

Zhongde Heavy Industries adheres to the bottom line of quality, provides users with high-quality equipment, and provides comprehensive after-sale protection for users to enjoy worry-free production. Our model is complete, advanced technology and reasonable prices, is your good choice for sand production.