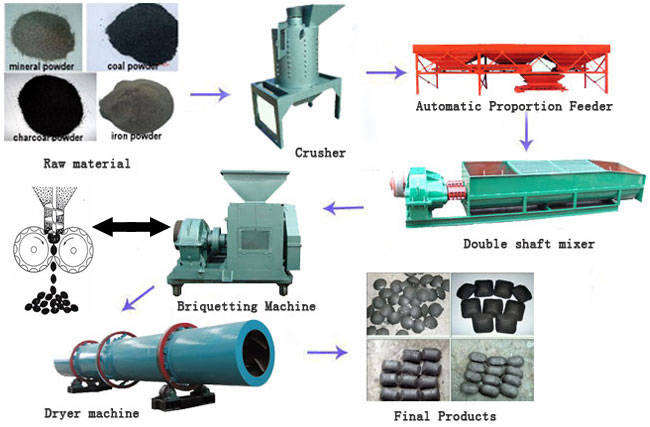

Brief description:no matter what kind of production process is, all need use briquette machine to complete briquetting raw materials, mixing all materials such as iron ore, iron concentrates, coke, coal and binder together, to press them into briquettes by briquette mac.

Power: 5.5-110kw

Capacity: 1-35TPH

Brief description: no matter what kind of production process is, all need use briquette machine to complete briquetting raw materials, mixing all materials such as iron ore, iron concentrates, coke, coal and binder together, to press them into briquettes by briquette mac.

Sponge iron also named direct reduction iron (DRI), it is the raw material for electric furnace steelmaking. In the sponge iron production process, no matter what kind of production process is, all need use briquette machine to complete briquetting raw materials, mixing all materials such as iron ore, iron concentrates, coke, coal and binder together, to press them into briquettes by briquette machine, then remove moisture, the drying briquettes can be smelted in furnace.

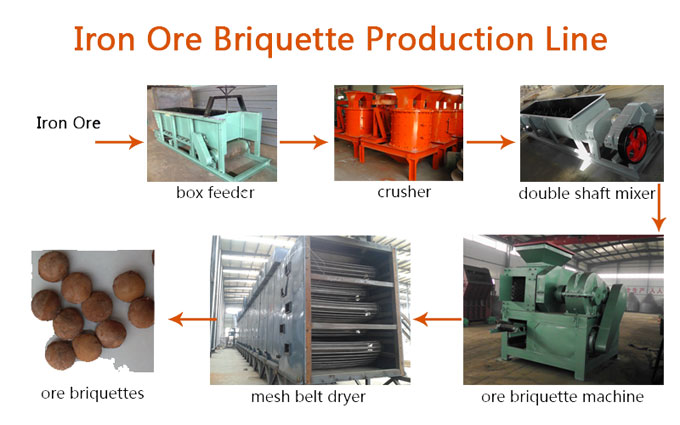

1.Hopper silo, or box type quantitative feeder, it load and convey raw materials to crusher evenly.

2.Two-stage crusher, the raw material be crushed in to the appropriate size, generally it is most suitable that not more than 5mm.

3.Liquid mixer, be used for mixing liquid binder, if use powdered binder, it should use a drying powder feeding equipment.

4.Horizontal two shafts mixer, evenly mixing raw materials, adhesives and water together, the adhesive will be evenly distributed in the raw materials so that achieve better strength, making briquettes better.

5.Carbon silicon briquette machine is a core of whole production line, it press materials into briquettes, the briquettes' size and shape can be customized, we can produce various shapes of rollers.

6.Vertical dryer, drying the wet briquettes which came from briquette machine, the briquettes can be dried to 3% water content, finished briquettes will put in storage or packaged.

7.Belt conveyor, connected to devices, it is guarantee for the whole manganese ore briquettes production line to realizes full automation.

1.The particle size of the raw material should be between 0-5mm.

2.Cannot contain impurities, especially large metal. Such as nails, or iron, rocks, it very likely damage roller and spindle.

3.The feeding of whole production line should be stable, even, ensure workloads of briquette machine stable, to get high efficiency of production.

| Model | Roller Diameter (mm) |

Capacity (t/h) |

| FTMQ290 | 290 | 1-2.5 |

| FTMQ360 | 360 | 3-5 |

| Heavy FTMQ360 | 360 | 3-5 |

| FTMQ430 | 430 | 5-8 |

| Heavy FTMQ430 | 430 | 5-8 |

| FTMQ500 | 500 | 8-11 |

| FTMQ650 | 650 | 10-15 |

| FTMQ750 | 750 | 20-25 |

| FTMQ850 | 850 | 20-28 |

| FTMQ1000 | 1000 | 25-35 |

NOTE: You can also send a message to us by this email info@sinoftm.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!