Raymond mill is also called Raymond roller mill. It is a new type of high-fineness grinding mill with high efficiency and closed circulation.

Feeding size: ≤30mm

Feeding size: ≤30mm

Capacity: 1-100 t/h

Capacity: 1-100 t/h

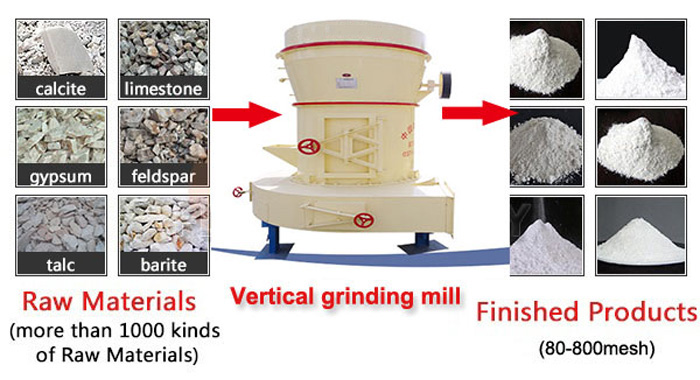

Raymond mill is often known as Raymond grinding mill. Raymond mill uses the centrifugal force principle to grind materials, which is suitable for grinding barite, calcite, talc, potassium feldspar, marble, limestone, silica sand, quartz, feldspar, talc, calcium carbonate, dolomite, phosphate rock and non inflammable and explosive minerals with less than 7Mohs hardness and below 6% humidity.

Raymond mill is easy to adapt to small and medium-sized mine, chemical industry, building materials, metallurgy and other industries. The finished product size can be adjusted discretionarily from 80-325 meshes and finished product size of some materials can reach up to 800 meshes.

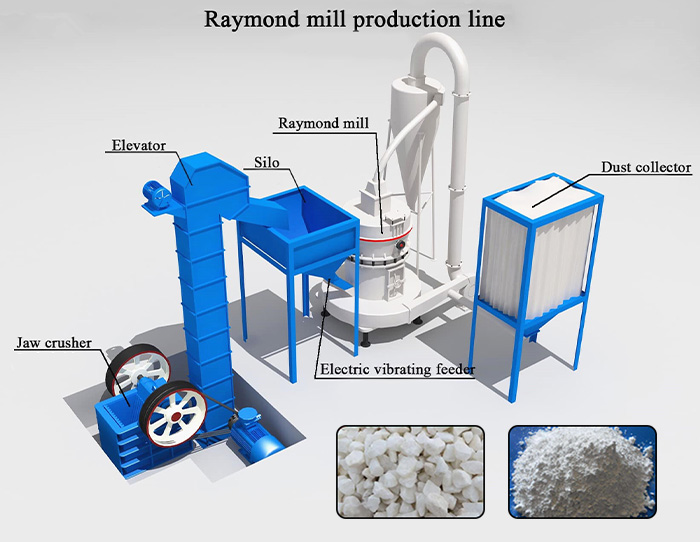

Jaw crusher, bucket elevator, electromagnetic vibrating feeder, electric motor, etc.

1. Three-dimensional structure, small occupied area.

2. The particle size of finished powder is ultrafine and homogeneous, which is the unique advantage that other milling equipment does not have.

3. The discharging fineness can be adjusted according to the fineness requirements, which has wide adjustment range and the finest is up to 600 meshes.

4. Special working principle. In a certain range, the wear of the grinding ring and roller does not affect the yield and fineness of finished product.

5. The electrical system adopts centralized control, the milling shop can basically realize no human operation, and the maintenance is convenient.

6. It is equipped with dust collector, which can conduct the excess gas in the Raymond mill into the dust collector to purify the exhaust gas.

7. Automatic oil feeding system increases the service life of the bearing and prolongs the service life of the equipment.

8. The air flow system has closed circulation to prevent dust pollution.

9. The equipment has smooth running, which is safe and reliable.

1. Feeding moisture: if the feeding moisture is too large, the material will stick together or adhere to the the inner wall of the crushing cavity, which will directly affect the efficiency of equipment.

2. The hardness of materials: if the feeding hardness must be within the prescribed scope, in this range, if the hardness of material is large, the corresponding grinding efficiency will be lower.

3. The composition of material products, if the feed material contains a large amount of fine powder, the fine powder will be directly glued to the inside of the device due to the electrostatic interaction, which will influence the discharging effect.

4. The wearing degree of the key components: the quality of the wearing parts determines the fineness of grinding material and production process.

Zhongde Heavy Industries has Raymond mill machine for sale, which has top quality, excellent performance and reasonable price. If you want to know more details, please leave us a message or click customer service. We will answer you as quickly as possible!

| Model | Output Size (mm) |

Shift output of different materia fineness(t) |

| 4525 | 0.173-0.044 | 16-176 |

| 4119 | 0.173-0.044 | 8-78 |

NOTE: You can also send a message to us by this email info@sinoftm.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!