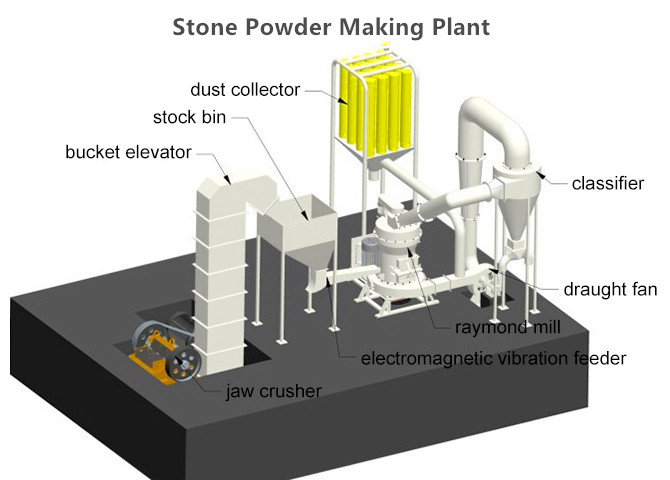

Powder grinding plant is generally composed of jaw crusher, bucket elevator, electro-vibrating feeder, mainframe and auxiliary engine of grinding mill, draught fan, dust-removing equipment, etc.

Applied Materials: cement, quartz, feldspar, barite, calcite, gypsum, limestone, dolomite, talc, marble, fluorite, etc.

Production Capacity:0.5-30t/h

Powder grinding plant adopts electric control, complete set of integrated operation, automatic production and the basic realization of unattended operation. The production line has convenient maintenance and efficient milling process, which is currently the commonly applied milling process.

Powder making plant is suitable for grinding non combustible and explosive materials with below 6%humidity and below 8 and less than 9.5Mohs hardness. It is widely used in mines, electric power, chemical, building materials, metallurgy, refractory materials, power plant desulfurization, asphalt mixing station, the highway industry, etc.

Jaw crusher -- > bucket type lifting machine -- > bin -- > vibrating feeder -- > host -- > classifier -- > powder collector -- > precipitator. The pipelines are connected between devices. When the production line is working, large bulk materials will be firstly crushed by the jaw crusher into the required size, and then sent to the silo by the bucket elevator. After that, the vibrating feeder will evenly send the materials to the mill. After grinding, the fine powder which reaches the production requirements will flow into the powder collector through the classifier and then discharged. The powder which does do not meet the required powder size will be returned to the mill for regrinding.

1. Stable operation, high automation degree, resource saving;

2. The product size can be adjusted in the range of 25-3000 mesh;

3. High production efficiency, high yield, low cost;

4. It can realize continuous production, the equipment has low failure rate;

5. It uses high-strength wear-resistant material, which has low loss and long service life;

6. The configuration can be adjusted according to the customer demand.

Zhongde Heavy Industries can not only provide reasonable supporting devices of industrial milling production line with reliable quality, wide selection ranges and high performance to price ratio, but also can provide the overall design and construction schemes for milling operations. Welcome to visit our company!

NOTE: You can also send a message to us by this email info@sinoftm.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!