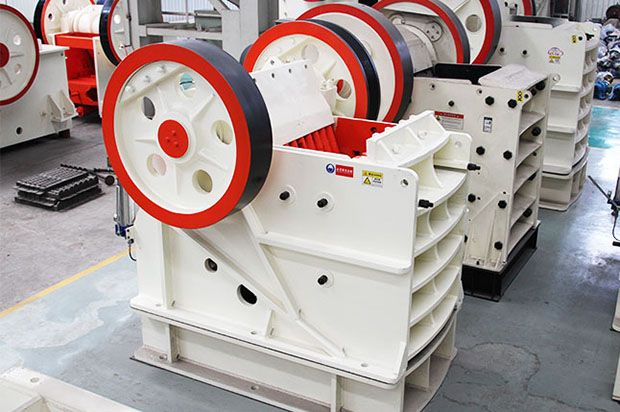

Jaw crushers are used mainly in first stage, primary crushing applications and are ideal for use in quarries and recycling demolition operations.

Feeding Size: 120-1500mm

Production Capacity: 5-2200t/h

Jaw Crushers are used for the rapid, powerful crushing and pre-crushing of medium hard, hard, brittle and tough materials. The variety of materials offered, their efficiency and safety make them ideal for crushing works in mining, quarry, construction, aggregate and other industries.

As the first choice of primary crushing, jaw crusher can be divided into coarse crusher and fine crusher. Its feeding size is 120mm~1500mm.

Jaw crushers are used in a wide variety of industries across many fields. Below are just some of the materials crushed by our customers:

1. Hard rock metallic and non-metallic ores: gold/silver/copper, wollastonite, barite, tungsten, quartz, coal, limestone

2. Aggregate: field stones, river rock, blast rock, lava rock

3. Construction waste: asphalt, concrete, bricks, pavers, etc.

4. Decorative stone industry waste: cuttings, remnants, granite scrap, marble, sandstone

5. Recycled materials: glass, metallic slag, porcelain, compressed metallic blocks

Large jaw crusher, medium jaw crusher, small jaw crusher

1. An excellent reliability

2. Safe, quick and easy maintenance

3. High throughput, high degree of size reduction

4. Breaking jaws made of wear resistant materials

5. Optimized performance, long life and a low cost per ton

6. Deep, symmetrical crushing chamber, easy settings adjustment, a large feed opening for its size.

Zhongde Heavy Industries offers a versatile, full line of jaw crushers available in several sizes for portable or stationary mounting, including the Hydra-Jaw?, combining advances in safety and productivity to optimize your quarry or mining operation. We have been designing jaw crushers in close cooperation with our customers for many years, and we know exactly what you need in order to boost your productivity.

| Model | Max.Feeding size (mm) | Capacity (t/h) |

| PE 150×250 | 125 | 1-3 |

| PE 200×300 | 180 | 2-6 |

| PE 200×350 | 180 | 3-10 |

| PE 250×400 | 210 | 5-21 |

| PE 400×600 | 340 | 16-64 |

| PE 500×750 | 425 | 40-110 |

| PE 600×750 | 500 | 80-240 |

| PE 600×900 | 500 | 50-160 |

| PE 750×1060 | 630 | 110-320 |

| PE 900×1200 | 750 | 220-380 |

| PE 1200×1500 | 1020 | 400-1000 |

| PE 1500×1800 | 1200 | 500-1200 |

| PEX 150×750 | 120 | 8-25 |

| PEX 250×750 | 210 | 13-35 |

| PEX 250×1000 | 210 | 16-52 |

| PEX 250×1200 | 210 | 20-61 |

| PEX 300×1300 | 250 | 16-105 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

NOTE: You can also send a message to us by this email info@sinoftm.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!